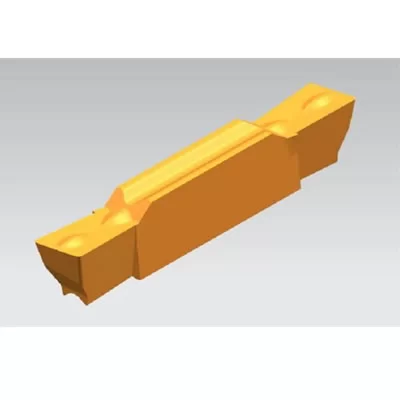

method of coarse milling of large modulus gear teeth with three-sided edge milling cutter

It is suitable for milling gears with large diameter by using three-sided milling cutter between teeth on common gear hobbing machine.

And for milling gears with a diameter greater than 2.5m, it needs to be carried out on a machine tool with a dedicated turret, this processing method, the gear teeth between the metal does not have to all become chips, so that part of the metal is long, because the three-sided milling cutter teeth than the finger-shaped milling cutter more than 4~6 times, it can correspondingly increase the feed per minute, thereby increasing the milling teeth productivity. Other aspects of the three-sided milling cutter between teeth, can greatly reduce the speed of each tool consumption of steel, so that cutting tool costs.

Three side milling cutter processing, only the peripheral blade to participate in cutting, and the knife gear flow force, good heat dissipation, chip is also convenient, improve the tool durability, and finger-shaped milling cutter closed cutting, not easy to dissipate heat, end teeth easily damaged, household ladder three side milling cutter than the finger-shaped milling cutter cost cheap, and good versatility, milling gear modulus, the number of teeth range is larger, unlike a finger milling cutter, a modulus is required.

Milling cutter Spacing for the number of teeth in more than 10, diameter is not greater than 2m large modulus spur gear, can be used on the common hobbing machine with three-sided milling cutter teeth, the knife bar 2 of the distance between the milling cutter equals the length of the common normal and processing allowances (along the milling cutter axis, the teeth of a single side finishing allowance generally take 1~1.6mm). The method of coarse milling large modulus gear tooth with three side milling cutter has the advantages of high efficiency, long tool life, low cost, good versatility and so on, and can be recycled to make other small parts.