Kugwiritsa Ntchito Moyenera End Mill

Kugwiritsa ntchito bwino mphero

Pamene mphero zovuta workpieces pa mphero Machining Center, mavuto otsatirawa ayenera kulabadira kugwiritsa ntchito manambala ulamuliro mapeto mphero wodula:

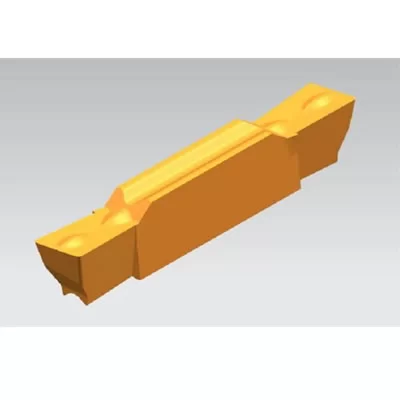

1. Mapeto mphero wodula ntchito clamping pakati Machining wa mapeto mphero wodula makamaka utenga kasupe achepetsa anapereka achepetsa mode, amene ali mu cantilever boma pamene ntchito. M'kati mphero, nthawi zina mapeto mphero wodula akhoza pang'onopang'ono kutambasula chofukizira chida, kapena ngakhale dontho kwathunthu, chifukwa mu chodabwitsa workpiece scrapping. Nthawi zambiri, chifukwa chake ndi chakuti pali filimu yamafuta pakati pa dzenje lamkati la chofukizira chida ndi mainchesi akunja a shank yodula mphero, zomwe zimapangitsa kuti pakhale mphamvu yokhotakhota yosakwanira. Chodulira mphero nthawi zambiri chimakutidwa ndi mafuta a antirust pochoka kufakitale. Ngati mafuta odulira osasungunuka m'madzi amagwiritsidwa ntchito podula, dzenje lamkati la chodulira lidzalumikizidwanso ndi nkhungu ngati filimu yamafuta. Pakakhala filimu yamafuta pa chogwirira ndi chodulira, zimakhala zovuta kuti wodulayo atseke chogwiriracho mwamphamvu, ndipo chodula mphero chizikhala chosavuta kumasula ndikugwa pakukonza. Choncho, mapeto mphero wodula ndi clamped, chogwiririra wa mapeto mphero wodula ndi dzenje lamkati la wodula achepetsa ayenera kutsukidwa ndi kuyeretsa madzimadzi ndiyeno clamped pambuyo zouma. Pamene m'mimba mwake wa mphero ndi lalikulu, ngakhale chogwirira ndi atsekereza zili zoyera, wodula akhoza kugwa. Pankhaniyi, chogwiriracho chokhala ndi notch yathyathyathya komanso njira yotsekera mbali yofananira iyenera kusankhidwa.

2. Kugwedezeka kwa mphero

Chifukwa cha kusiyana kwakung'ono pakati pa chodula chomaliza ndi chotchinga chodula, wodulayo amatha kunjenjemera panthawi yopanga makina. The kugwedera adzapanga kudula kuchuluka kwa m'mphepete zozungulira mapeto mphero wodula wosagwirizana, ndi kudula kukula ndi lalikulu kuposa mtengo choyambirira anapereka, zomwe zidzakhudza kulondola Machining ndi moyo utumiki wa wodulayo. Komabe, pamene poyambira m'lifupi ndi laling'ono kwambiri, chida akhoza kunjenjemera mwadala, ndi chofunika poyambira m'lifupi angapezeke mwa kuonjezera kudula kukula, koma mu nkhani iyi, matalikidwe pazipita mapeto mphero ayenera kuchepetsedwa m'munsimu 0.02mm, apo ayi. kudula kokhazikika sikungachitike. Pang'ono pomwe kugwedezeka kwa chodulira chosalowerera ndale kumakhala bwino. Pamene kugwedezeka kwa chida kumachitika, liwiro lodulira ndi liwiro la chakudya liyenera kuchepetsedwa. Ngati pali kugwedezeka kwakukulu pambuyo poti onse achepetsedwa ndi 40%, kuchuluka kwa zida zopsereza kuyenera kuchepetsedwa. Ngati resonance imapezeka mu makina opangira makina, zikhoza kukhala chifukwa cha zinthu monga kuthamanga kwambiri kwa kudula, kusasunthika kwa dongosolo la chida chifukwa cha kupatuka kwa liwiro la chakudya, mphamvu yokwanira ya clamping ya workpiece, ndi mawonekedwe a workpiece kapena clamping njira. Panthawiyi, ndikofunikira kusintha kuchuluka kwa kudula ndikuwonjezera kuchuluka kwa kudula.

Kusasunthika kwa dongosolo la zida ndi kuwongolera kwa liwiro la chakudya.

3. Mapeto kudula kwa mapeto mphero wodula

Mu NC mphero ya kufa patsekeke, pamene mfundo kudula ndi concave mbali kapena zakuya patsekeke, m'pofunika kuwonjezera kutambasuka kwa mapeto mphero wodula. Ngati mphero yayitali yam'mphepete ikagwiritsidwa ntchito, ndiyosavuta kutulutsa kugwedezeka ndikuwononga zida chifukwa chapatuka kwake kwakukulu. Choncho, mu ndondomeko ya Machining, ngati kokha kudula m'mphepete pafupi ndi mapeto a chida chofunika nawo kudula, ndi bwino kusankha yochepa m'mphepete yaitali shank mapeto mphero ndi yaitali okwana kutalika kwa chida. Pamene lalikulu m'mimba mwake mapeto mphero ntchito yopingasa CNC makina chida pokonza workpieces, chifukwa mapindikidwe lalikulu chifukwa cha imfa kulemera kwa chida, chidwi kwambiri ayenera kuperekedwa kwa mavuto amene n'zosavuta kuchitika kumapeto kudula. Pamene mphero yaitali m'mphepete ayenera kugwiritsidwa ntchito, kudula liwiro ndi chakudya liwiro ayenera kuchepetsedwa kwambiri.

4. Kusankha kudula parametizi

Kusankha kudula liwiro makamaka zimadalira zinthu za workpiece kuti kukonzedwa; kusankha liwiro chakudya makamaka zimadalira zinthu workpiece kuti kukonzedwa ndi awiri a mapeto mphero. Zitsanzo za zida zochokera kwa opanga zida zakunja zimamangiriridwa ndi tebulo losankhira zida kuti mufotokozere. Komabe, kusankha magawo odulira kumakhudzidwa ndi zinthu zambiri monga chida cha makina, dongosolo la zida, mawonekedwe a workpiece kuti azikonzedwa ndi njira yokhomerera. Kuthamanga kwachangu ndi liwiro la chakudya ziyenera kusinthidwa malinga ndi momwe zilili. Pamene moyo chida ndi patsogolo, kudula liwiro ndi liwiro chakudya akhoza kuchepetsedwa bwino; pamene chip sichili bwino, liwiro la kudula likhoza kuwonjezeka bwino.

5. Kusankhidwa kwa kudula mode

Kugwiritsa ntchito mphero kumathandizira kupewa kuwonongeka kwa tsamba ndikusintha moyo wa zida. Komabe, mfundo ziwiri ziyenera kudziwidwa: ① ngati zida zamakina wamba zimagwiritsidwa ntchito popanga, ndikofunikira kuthetsa kusiyana pakati pa njira yodyetsera; ② pakakhala filimu ya okusayidi kapena wosanjikiza wina wowumitsa wopangidwa ndi kuponyera ndi kupanga njira pamwamba pa chogwiriracho, ndikofunikira kugwiritsa ntchito mphero yobwerera.

6. Kugwiritsa ntchito mphero za carbide

Mphero zachitsulo zothamanga kwambiri zimakhala ndi ntchito zosiyanasiyana komanso zofunikira. Ngakhale mikhalidwe yodulirayo sinasankhidwe bwino, sipadzakhala mavuto ambiri. Ngakhale carbide mapeto mphero wodula ali ndi kukana kwabwino kuvala mu kudula mkulu-liwiro, ntchito zosiyanasiyana zake si lonse monga mkulu-liwiro zitsulo mapeto mphero wodula, ndi mikhalidwe kudula ayenera mosamalitsa kukwaniritsa zofunika ntchito wa wodulayo.