Milling Cutter Basics

milling cutter hauv paus

Dab tsi yog milling cutter?

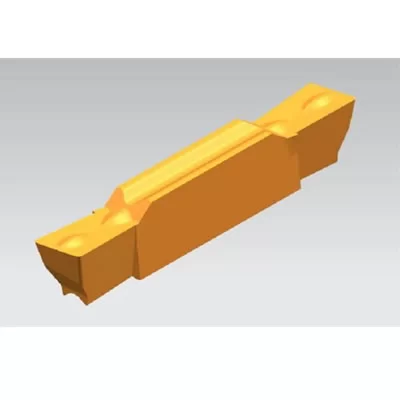

Los ntawm kev pom kev tshaj lij, milling cutter yog cov cuab yeej txiav siv rau milling. Nws tuaj yeem tig thiab muaj ib lossis ntau qhov txiav hniav. Thaum lub sij hawm milling txheej txheem, txhua tus hniav txiav lub workpiece pub intermittently. Nws yog tsuas yog siv nyob rau hauv machining dav hlau, cov kauj ruam, grooves, tsim nto thiab txiav workpieces ntawm milling tshuab. Ib qho av nqaim yog tsim rau ntawm lub flank los tsim lub kaum sab xis, thiab nws lub neej yog siab dua vim qhov tsim nyog txiav lub kaum sab xis. Sab nraum qab ntawm lub suab milling cutter muaj peb hom: kab ncaj nraim, nkhaus thiab quav kab. Linear backs feem ntau yog siv rau cov hniav zoo nkauj cutters. Curves thiab creases muaj cov hniav zoo zog thiab tuaj yeem tiv taus cov khoom hnyav, thiab feem ntau yog siv rau cov hniav ntxhib hniav milling cutters.

Dab tsi yog cov milling cutters?

Cylindrical milling cutter: siv rau machining dav hlau ntawm kab rov tav milling tshuab. Cov hniav raug faib rau ntawm qhov ncig ntawm lub tshuab txiav thiab muab faib ua cov hniav ncaj thiab muab kauv hniav raws li cov hniav zoo nkauj. Raws li tus naj npawb ntawm cov hniav, muaj ob hom ntawm cov hniav ntxhib thiab cov hniav zoo. Muab kauv cov hniav ntxhib-cov hniav milling cutter muaj ob peb cov hniav, siab hniav zog, loj nti qhov chaw, haum rau ntxhib machining; fine-tooth milling cutter yog haum rau xov;

Lub ntsej muag milling cutter: siv rau ntsug milling tshuab, ntsej muag milling tshuab lossis gantry milling tshuab. Lub dav hlau kawg ntawm lub ntsej muag thiab qhov ncig muaj cov hniav thiab cov hniav ntxhib thiab cov hniav zoo. Cov qauv muaj peb hom: ib hom, ntxig hom thiab indexable hom;

End zeb: siv rau tshuab grooves thiab kauj ruam nto. Cov hniav yog nyob rau ntawm ib ncig thiab lub ntsej muag kawg. Lawv tsis tuaj yeem noj hauv axial kev taw qhia thaum lub sijhawm ua haujlwm. Thaum kawg zeb muaj cov hniav kawg hla ntawm qhov chaw, nws tuaj yeem muab axially pub;

Peb-sided ntug milling cutter: siv los tshuab ntau yam grooves thiab kauj ruam ntsej muag nrog cov hniav ntawm ob sab thiab ncig;

Lub kaum sab xis milling cutter: siv los zeb ib zawj ntawm lub kaum sab xis, ob lub kaum sab xis thiab ob lub kaum sab xis milling cutters;

Pom hniav milling cutter: siv los tshuab sib sib zog nqus grooves thiab txiav workpieces nrog ntau cov hniav ntawm qhov ncig. Txhawm rau txo qhov kev sib txhuam ntawm lub tshuab txiav, muaj 15' ~ 1 ° theem nrab declination ntawm ob sab. Tsis tas li ntawd, muaj qhov tseem ceeb milling cutters, dovetail milling cutters, T-slot milling cutters thiab ntau yam sib sau cutters.

Dab tsi yog qhov yuav tsum tau ua rau kev tsim khoom ntawm kev txiav ib feem ntawm milling cutter?

Cov khoom siv dav siv rau kev tsim cov milling cutters suav nrog cov cuab yeej siv ceev ceev, cov khoom siv nyuaj xws li tungsten-cobalt thiab titanium-cobalt-raws li hard alloys. Tau kawg, muaj qee cov khoom siv hlau tshwj xeeb uas tuaj yeem siv los ua cov milling cutters. Feem ntau, cov khoom siv hlau no muaj cov khoom nram qab no:

1) Kev ua tau zoo ntawm cov txheej txheem: forging, ua thiab sharpening yog ib qho yooj yim;

2) High hardness thiab hnav tsis kam: Ntawm qhov kub thiab txias, qhov txiav yuav tsum muaj qhov nyuaj txaus los txiav rau hauv qhov chaw ua haujlwm; nws muaj kev hnav tsis kam, lub cuab yeej tsis hnav thiab ua rau lub neej ua haujlwm ntev;

3) Kev ua haujlwm kub zoo: lub cuab yeej yuav tsim kom muaj cua sov ntau thaum lub sijhawm txiav, tshwj xeeb tshaj yog thaum txiav ceev, qhov kub yuav siab heev. Yog li ntawd, cov cuab yeej siv yuav tsum muaj cov cua kub zoo, txawm tias qhov kub thiab txias. Nws muaj peev xwm tuav tau siab hardness thiab muaj peev xwm mus txuas ntxiv txiav. Hom kub hardness no tseem hu ua thermosetting lossis liab hardness.

4) Lub zog siab thiab zoo toughness: Thaum lub sij hawm txiav cov txheej txheem, lub cuab yeej yuav tsum tau dais ib tug loj cuam tshuam quab yuam, yog li cov cuab yeej siv yuav tsum muaj lub zog siab, txwv tsis pub nws yuav yooj yim tawg thiab puas. Txij li thaum lub milling cutter yog raug kev poob siab thiab kev co, cov khoom siv milling cutterkuj yuav tsum muaj zoo toughness, yog li ntawd nws tsis yooj yim rau nti thiab nti.

Yuav ua li cas tom qab milling cutter passivated?

1. Los ntawm cov duab ntawm riam ntug, riam ntug muaj lub ci dawb;

2. Los ntawm cov duab ntawm cov nti, cov chips ua ntxhib thiab flake-puab, thiab cov xim ntawm cov chips yog ntshav thiab cov pa luam yeeb vim qhov kub ntawm cov chips nce;

3. Cov txheej txheem milling ua rau muaj kev vibrations hnyav heev thiab suab nrov txawv txav;

4. Lub roughness ntawm qhov chaw ntawm lub workpiece yog heev tsis zoo, thiab nto ntawm lub workpiece muaj ci me ntsis nrog rau cov kab mob los yog ripples;

5. Thaum milling steel qhov chaw nrog carbide milling cutters, ntau qhov hluav taws kub pos huab feem ntau yoov;

6. Milling steel qhov chaw nrog high-speed steel milling cutters, yog tias txias nrog roj lubrication, yuav ua rau muaj pa taws ntau.

Thaum lub milling cutter yog passivated, nws yuav tsum tau nres nyob rau hauv lub sij hawm los xyuas qhov hnav ntawm lub milling cutter. Yog tias hnav me ntsis, cov ntug txiav tuaj yeem siv los zom cov ntug txiav thiab rov qab siv dua. Yog tias hnav hnyav, nws yuav tsum tau ua kom zoo kom tsis txhob muaj qhov milling cutter ntau dhau. Hnav