Kev Tsim Kho Thiab Kev Tsim Nyog Ntawm Ceramic Inserts Materials

Kev tsim kho thiab kev sib txawv ntawm cov ntaub ntawv ceramic hniav

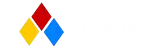

Nyob rau hauv machining, lub cuab tam yeej ib txwm hu ua "industrially ua cov hniav", thiab txiav kev ua tau zoo ntawm cov cuab yeej cuab tam yog ib tug ntawm cov tseem ceeb yam tseem ceeb txiav txim siab nws ntau lawm efficiency, ntau lawm nqi thiab ua zoo. Yog li ntawd, qhov kev xaiv raug ntawm cov cuab yeej txiav yog qhov tseem ceeb, cov riam ceramic, nrog rau lawv cov cua sov ua haujlwm zoo, hnav tsis kam thiab tshuaj lom neeg ruaj khov, qhia qhov zoo ntawm cov cuab yeej tsoos tsis sib xws hauv kev kub ceev txiav thiab txiav nyuaj-rau. -machine cov ntaub ntawv, thiab cov ntaub ntawv tseem ceeb ntawm cov riam ceramic yog Al thiab Si. Cov ntsiab lus nplua nuj nyob rau hauv lub ntiaj teb crust tuaj yeem hais tias yog inexhaustible thiab inexhaustible. Yog li ntawd, daim ntawv thov kev cia siab ntawm cov cuab yeej ceramic tshiab yog dav heev.

Ua ntej, hom khoom siv ceramic

Kev nce qib ntawm cov khoom siv ceramic yog tsom rau kev txhim kho kev ua haujlwm ntawm cov khoom siv niaj hnub ceramic, refining nplej, tivthaiv compounding, txheej, txhim kho sintering txheej txheem thiab tsim cov khoom tshiab, thiaj li yuav tau txais kev kub siab, hnav tsis kam thiab tsis kam. Kev ua haujlwm zoo heev chipping thiab tuaj yeem ua tau raws li qhov xav tau ntawm high-speed precision machining. Henan lub koom haum ntawm Superhard Materials tuaj yeem faib cov khoom siv ceramic rau hauv peb pawg: alumina, silicon nitride thiab boron nitride (cov cuab yeej cubic boron nitride). Nyob rau hauv lub tshav pob ntawm cov hlau txiav, alumina ceramic hniav thiab silicon nitride ceramic hniav yog sib sau ua ke hu ua ceramic hniav; Nyob rau hauv cov ntaub ntawv inorganic non-metallic, cubic boron nitride cov ntaub ntawv belongs rau ib tug loj chav kawm ntawv ntawm ceramics. Cov hauv qab no yog cov yam ntxwv ntawm peb hom ceramics.

(1) Alumina (Al2O3)-raws li ceramic: Ni, Co, W, los yog cov zoo li yog ntxiv raws li ib tug binder hlau rau cov carbide-raws li ceramic, thiab lub zog sib txuas ntawm alumina thiab carbide tuaj yeem txhim kho. Nws muaj qhov zoo hnav tsis kam thiab kub tsis kam, thiab nws qhov kub thiab txias tshuaj stability tsis yooj yim rau interdif los yog tshuaj tiv thaiv nrog hlau. Yog li ntawd, alumina-based ceramic cutters muaj cov ntawv thov dav tshaj plaws, haum rau cov hlau thiab cam khwb cia hlau. High-speed machining ntawm nws cov alloys; vim kev txhim kho thermal poob siab tsis kam, nws kuj tuaj yeem siv rau milling lossis kev npaj nyob rau hauv kev cuam tshuam tej yam kev mob, tab sis nws tsis haum rau kev ua txhuas alloys, titanium alloys thiab niobium alloys, txwv tsis pub nws yog nquag siv tshuaj.

(2) Silicon nitride (Si3N4)-raws li ceramic cutter: Nws yog ib qho ceramic ua los ntawm kev ntxiv tus nqi ntawm cov hlau carbide thiab cov hlau ntxiv dag zog rau cov silicon nitride matrix, thiab siv cov khoom sib xyaw ua kom muaj zog (tseem hu ua dispersion. ntxiv dag zog rau cov nyhuv). Nws yog tus cwj pwm los ntawm kev ua haujlwm siab, zoo hnav tsis kam, zoo kub tsis kam thiab oxidation tsis kam, thiab tshuaj lom neeg cov tshuaj tiv thaiv ntawm silicon nitride thiab carbon thiab hlau ntsiab yog me me, thiab cov kev sib txhuam tseem tsawg. Haum rau kev ua tiav, semi-finishing, xov lossis semi-finishing.

(3) Boron nitride ceramic (cubic boron nitride cutter): siab hardness, hnav tsis kam, kub tsis kam, zoo thermal stability, zoo thermal conductivity, tsis tshua muaj kev sib txhuam coefficient, thiab me me coefficient ntawm linear expansion. Piv txwv li, Hualing cubic boron nitride cuab tam BN-S20 qib yog siv rau roughing hardened steel, BN-H10 qib yog siv rau kev kub ceev xov hardened steel, BN-K1 qib yog ua tiav high hardness cam khwb cia hlau, BN-S30 qib siab ceev txiav. Cov hmoov tshauv cam khwb cia hlau yog kev lag luam ntau dua li cov khoom siv ceramic.

Qhov thib ob, cov yam ntxwv ntawm cov cuab yeej ceramic

Cov yam ntxwv ntawm cov cuab yeej ceramic: (1) zoo hnav tsis kam; (2) kub tsis kam, zoo liab hardness; (3) cov cuab yeej durability yog ob peb zaug lossis ntau zaus ntau dua li cov cuab yeej siv ib txwm siv, txo cov cuab yeej hloov pauv thaum ua, ua kom cov taper me me thiabhigh precision ntawm lub workpiece yuav tsum machined; (4) tsis tsuas yog siv tau rau roughing thiab xov ntawm high-hardness cov ntaub ntawv, tab sis kuj rau machining nrog loj tej yam xws li milling, npaj, interrupted txiav thiab dawb paug roughing; (5) Thaum cov hniav ceramic raug txiav, kev sib txhuam nrog cov hlau me me, kev txiav tsis yooj yim rau kev sib txuas nrog cov hniav, cov ntug tsim tsis yooj yim tshwm sim, thiab kev kub ceev txiav tuaj yeem ua tau.

Piv nrog cov cemented carbide inserts, ceramic inserts tuaj yeem tiv taus qhov kub thiab txias ntawm 2000 ° C, thaum cov alloys nyuaj ua mos ntawm 800 ° C; yog li cov cuab yeej ceramic muaj qhov kub siab dua cov tshuaj ruaj khov thiab tuaj yeem txiav ntawm kev kub ceev, tab sis qhov tsis zoo yog ceramic inserts. Lub zog thiab toughness yog tsawg thiab yooj yim tawg. Tom qab ntawd, boron nitride ceramics (tom qab no hu ua cubic boron nitride cov cuab yeej) tau qhia, uas yog siv los tig, milling, thiab tho txawv superhard cov ntaub ntawv. Lub hardness ntawm cubic boron nitride cutters yog ntau dua li ntawm ceramic inserts. Vim nws cov hardness siab, nws tseem hu ua superhard khoom nrog pob zeb diamond. Nws yog feem ntau siv los ua cov ntaub ntawv nrog hardness siab dua HRC48. Nws muaj qhov kub thiab txias hardness zoo heev - txog li 2000 ° C, txawm hais tias nws yog nkig ntau dua li cov cemented carbide hniav, tab sis tau txhim kho kev cuam tshuam lub zog thiab crush kuj piv rau alumina ceramic cov cuab yeej. Tsis tas li ntawd, qee qhov tshwj xeeb cubic boron nitride cov cuab yeej (xws li Huachao Super Hard BN-K1 thiab BN-S20) tuaj yeem tiv taus cov nti ntawm cov khoom siv ntxhib thiab tuaj yeem tiv taus qhov cuam tshuam ntawm kev sib tshuam machining thiab ua tiav. Kev hnav thiab txiav cov cua sov, cov yam ntxwv no tuaj yeem ua tau raws li kev ua haujlwm nyuaj ntawm cov hlau tawv tawv thiab siab hardness cam khwb cia hlau nrog cubic boron nitride cov cuab yeej.