Slotting Ntawm Hardened Steel Nrog PCBN Cutter

Slotting ntawm hardened steel nrog PCBN cutter

Nyob rau hauv kaum xyoo dhau los, precision grooving ntawm hardened steel qhov chaw nrog polycrystalline cubic boron nitride (PCBN) inserts tau maj mam hloov tsoos tsoos sib tsoo. Tyler Economan, tus thawj coj ntawm kev sib tw engineering ntawm Index, Tebchaws Asmeskas, tau hais tias, "Feem ntau, kev sib tsoo grooves yog txheej txheem ruaj khov dua uas muab qhov tseeb dua qhov tseeb dua qhov grooving. Txawm li cas los xij, tib neeg tseem xav ua kom tiav cov haujlwm ntawm lub tshuab dhos. Ntau yam kev ua haujlwm yuav tsum tau ua. "

Ntau yam khoom siv ua haujlwm uas tau ua kom tawv muaj xws li kev kub ceev steel, tuag steel, bearing steel thiab alloy steel. Tsuas yog cov hlau ferrous tuaj yeem ua kom tawv, thiab cov txheej txheem hardening feem ntau yog siv rau cov pa roj carbon tsawg. Los ntawm kev kho hardening, sab nraud hardness ntawm workpiece tuaj yeem ua kom siab dua thiab hnav, thaum sab hauv muaj zog dua. Cov khoom ua los ntawm cov hlau tawv tawv muaj xws li mandrels, axles, connectors, tsav log, camshafts, gears, bushings, tsav shafts, bearings, thiab lwm yam.

Txawm li cas los xij, "cov ntaub ntawv nyuaj" yog cov txheeb ze, hloov lub tswv yim. Qee tus neeg xav tias cov khoom siv ua haujlwm nrog lub hardness ntawm 40-55 HRC yog cov ntaub ntawv nyuaj; lwm tus ntseeg hais tias qhov hardness ntawm cov ntaub ntawv nyuaj yuav tsum yog 58-60 HRC los yog siab dua. Hauv pawg no, PCBN cov cuab yeej siv tau.

Tom qab induction hardening, txheej txheej txheej txheej tuaj yeem ncav cuag 1.5 hli tuab thiab qhov hardness tuaj yeem ncav cuag 58-60 HRC, thaum cov khoom hauv qab txheej txheej feem ntau yog softer. Nyob rau hauv cov ntaub ntawv no, nws yog ib qho tseem ceeb kom paub meej tias feem ntau ntawm cov txiav yog ua nyob rau hauv lub saum npoo hardened txheej.

Cov cuab yeej siv tshuab nrog lub zog txaus thiab rigidity yog qhov tsim nyog rau grooving ntawm hardened qhov chaw. Raws li Economan, "Qhov zoo dua qhov rigidity ntawm lub tshuab cuab yeej thiab lub zog siab dua, qhov zoo dua qhov grooving ntawm cov khoom hardened. Rau cov khoom siv ua haujlwm nrog lub hardness ntawm ntau tshaj 50 HRC, ntau lub teeb tshuab cov cuab yeej tsis ua raws li qhov yuav tsum tau ua. Yog hais tias lub tshuab muaj peev xwm (lub zog, torque, thiab tshwj xeeb tshaj yog rigidity), lub machining tsis tuaj yeem ua tiav. "

Rigidity yog ib qho tseem ceeb heev rau lub workpiece tuav cov cuab yeej vim hais tias qhov kev sib cuag nto ntawm lub txiav ntug nrog lub workpiece yog loj thaum lub sij hawm grooving txheej txheem, thiab lub cuab tam exerts ib tug zoo kawg nkaus lub zog ntawm lub workpiece. Thaum clamping hardened steel workpieces, ib tug dav clamp yuav siv tau los disperse lub clamping nto. Paul Ratzki, tus thawj tswj hwm kev lag luam ntawm Sumitomo Electric Hard Alloy Co., tau hais tias, "Cov khoom yuav tsum tau ua haujlwm yuav tsum muaj kev txhawb nqa ruaj khov. Thaum machining cov ntaub ntawv hardened, lub vibration thiab lub cuab tam siab generated yog ntau loj dua thaum machining zoo tib yam workpieces, uas yuav ua rau lub workpiece clamping. Tsis tuaj yeem ya tawm ntawm lub tshuab, lossis ua rau CBN hniav tuaj yeem nti lossis tawg. "

Lub shank uas tuav lub grooving ntxig yuav tsum yog luv li sai tau kom txo qis overhang thiab ua kom cov cuab yeej rigidity. Matthew Schmitz, tus thawj coj ntawm GRIP cov khoom ntawm Isca, taw qhia tias feem ntau, cov cuab yeej monolithic yog qhov tsim nyog rau grooving ntawm cov ntaub ntawv tawv. Txawm li cas los xij, lub tuam txhab kuj tseem muaj cov txheej txheem modular grooving. "Lub shank modular tuaj yeem siv rau hauv machining qhov xwm txheej uas cov cuab yeej ua rau tsis ua haujlwm tam sim," nws hais. "Koj tsis tas yuav hloov tag nrho shank, koj tsuas yog yuav tsum tau hloov cov khoom kim dua. Lub shank modular kuj muaj ntau yam kev xaiv machining. Iskar's Grip modular system tuaj yeem ntsia tau rau hauv ntau yam khoom sib txawv. Koj tuaj yeem siv lub cuab yeej nrog 7 cov hniav sib txawv rau 7 cov khoom lag luam lossis ib tus lej ntawm cov hniav rau kev ua haujlwm sib txawv Cov khoom sib txawv nrog qhov dav. "

Sumitomo Electric tus tuav cov cuab yeej rau tuav CGA-hom inserts siv txoj kev clamping sab saum toj uas rub cov hniav rov qab rau hauv lub tuav. Tus tuav no tseem nta ib sab fastening ntsia hlau los pab txhim kho tuav ruaj khov thiab ntev lub cuab yeej siv. Rich Maton, tus pabtus thawj coj ntawm lub tuam txhab tsim lub tuam txhab, hais tias, "Cov cuab yeej no yog tsim los rau grooving ntawm hardened workpieces. Yog hais tias cov hniav txav nyob rau hauv lub tuav, cov hniav hnav lub sij hawm thiab lub cuab tam lub neej hloov. kev lag luam (xws li 50-100 lossis 150 workpieces ib ntus), qhov kev kwv yees ntawm lub neej cuab yeej tseem ceeb tshwj xeeb, thiab kev hloov pauv hauv lub neej ntawm cov cuab yeej tuaj yeem cuam tshuam rau kev tsim khoom. "

Raws li cov lus ceeb toom, Mitsubishi Materials 'GY series Tri-Lock modular grooving system yog sib piv hauv kev nruj rau cov hniav chucks. Lub kaw lus ntseeg tau tuav lub grooving hniav los ntawm peb cov lus qhia (peripheral, pem hauv ntej thiab sab saum toj). Nws ob txoj kev tsim qauv tiv thaiv cov hniav los ntawm kev tsiv tawm thaum lub sij hawm grooving: V-shaped projection tiv thaiv cov hniav los ntawm kev txav mus rau sab; tus yuam sij kev nyab xeeb tshem tawm kev txav mus tom ntej ntawm cov hniav tshwm sim los ntawm kev txiav quab yuam thaum lub sijhawm ua haujlwm.

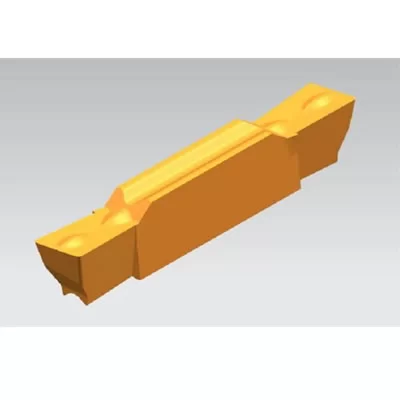

Feem ntau siv grooving inserts rau hardened steel qhov chaw xws li yooj yim square inserts, sib sau inserts, slotted inserts, thiab lwm yam. Feem ntau, cov grooves txiav yuav tsum muaj qhov zoo ntawm qhov tiav vim tias lawv muaj qhov sib txuas, thiab qee qhov yog O-rings lossis snap nplhaib grooves. Raws li Mark Menconi, tus kws tshaj lij cov khoom lag luam ntawm Mitsubishi Materials, "Cov txheej txheem no tuaj yeem muab faib ua txoj kab nruab nrab hauv qhov zawj machining thiab sab nraud txoj kab uas hla groove machining, tab sis feem ntau grooving ua haujlwm yuav tsum tau txiav npluav, suav nrog lub teeb kov precision ntawm li 0.25 hli qhov tob ntawm kev txiav. tag nrho txiav nrog qhov tob txog li 0.5mm. "

Lub grooving ntawm hardened steel yuav tsum tau siv cov cuab yeej nrog hardness siab dua, zoo hnav tsis kam thiab haum geometry. Tus yuam sij yog los xyuas seb puas yuav tsum tau siv cov carbide insert, ceramic insert los yog PCBN insert. Schmitz tau hais tias, "Kuv yuav luag ib txwm xaiv carbide inserts thaum machining workpieces nrog hardnesses qis dua 50 HRC. Rau workpieces nrog ib tug hardness ntawm 50-58 HRC, ceramic inserts yog ib qho kev xaiv pheej yig heev. Tsuas yog thaum lub workpiece CBN inserts yuav tsum tau txiav txim siab rau hardness txog 58 HRC. CBN inserts yog tshwj xeeb tshaj yog haum rau machining xws li cov ntaub ntawv nyuaj vim hais tias lub machining mechanism tsis yog ib tug txiav cov ntaub ntawv tab sis ib tug cuab yeej / workpiece interface. Qhuav cov khoom.

Rau grooving ntawm hardened steel qhov chaw nrog ib tug hardness ntawm tshaj 58 HRC, nti tswj tsis yog ib qho teeb meem. Txij li thaum qhuav grooving feem ntau yog siv, cov chips zoo li cov plua plav lossis cov khoom me me thiab tuaj yeem raug tshem tawm ntawm tes tshuab. Sumitomo Electric's Maton tau hais tias, "Feem ntau, hom swarf no yuav tawg thiab tawg thaum nws tsoo ib yam dab tsi, yog li kev sib cuag ntawm swarf nrog lub workpiece yuav tsis ua rau lub workpiece puas. Yog tias koj tuav lub swarf, lawv yuav tsoo ntawm koj txhais tes."

Ib qho ntawm cov laj thawj vim li cas CBN inserts tsim nyog rau kev txiav qhuav yog tias txawm hais tias lawv cov cua sov ua haujlwm zoo heev, kev ua haujlwm tau txo qis heev nyob rau hauv cov ntaub ntawv ntawm qhov kub thiab txias. Economan hais tias, "Qhov tseeb, thaum CBN ntxig yog nyob rau hauv kev sib cuag nrog cov khoom siv ua haujlwm, nws ua kom sov ntawm kev txiav ntawm lub taub, tab sis vim tias CBN ntxig yog qhov hloov tau yooj yim rau qhov kub thiab txias, nws yog qhov nyuaj rau kev ua kom txias kom ruaj khov. kub. Xeev. CBN nyuaj heev, tab sis nws kuj yog nkig heev thiab tej zaum yuav tawg vim qhov kub thiab txias. "

Thaum txiav cov hlau tsis muaj zog (xws li 45-50 HRC) nrog cov cemented carbide, ceramic los yog PCBN inserts, cov chips generated yuav tsum luv li sai tau. Qhov no zoo tshem tawm cov cua sov ntawm kev txiav hauv cov khoom siv thaum lub sij hawm txiav cov txheej txheem vim hais tias cov chips tuaj yeem nqa tawm ntau cov cua sov.

Iskar's Schmitz kuj pom zoo tias cov cuab yeej ua tiav hauv lub xeev "inverted". Nws piav qhia tias, "Thaum txhim kho lub cuab yeej ntawm lub tshuab cuab yeej, lub tshuab tsim cov cuab yeej nyiam raug ntsia los ntawm kev txiav cov hniav ntsej muag, vim qhov no tso cai rau cov cuab yeej tsim khoom siv.Kev sib hloov ntawm lub workpiece kom qis qis rau ntawm lub tshuab rail kom lub tshuab ruaj khov. Txawm li cas los xij, thaum cov hniav raug txiav rau hauv cov khoom siv ua haujlwm, cov chips tsim yuav nyob twj ywm ntawm cov hniav thiab cov khoom ua haujlwm. Yog tias lub cuab yeej tig rov qab thiab lub cuab yeej txuas rau pem hauv ntej, cov hniav yuav tsis pom, thiab cov nti ntws yuav cia li khiav tawm ntawm qhov chaw txiav nyob rau hauv qhov kev txiav txim ntawm lub ntiajteb txawj nqus. "

Surface hardening yog ib txoj hauv kev yooj yim los txhim kho hardness ntawm cov pa roj carbon tsawg. Lub hauv paus ntsiab lus yog nce cov ntsiab lus carbon ntawm ib qho tob hauv qab ntawm cov khoom siv. Thaum lub grooving qhov tob tshaj qhov tuab ntawm cov txheej txheej hardened, qee qhov teeb meem yuav tshwm sim vim qhov kev hloov ntawm cov grooving hniav los ntawm cov khoom nyuaj rau cov khoom softer. Txog qhov kawg no, cov tuam txhab lag luam tau tsim ntau qib hniav rau ntau hom khoom siv ua haujlwm.

Duane Drape, tus thawj coj muag khoom ntawm Horn (USA), tau hais tias, "Thaum hloov los ntawm cov khoom siv tawv dua rau cov khoom siv softer, tus neeg siv tsis tas xav hloov cov hniav, yog li peb yuav tsum nrhiav cov cuab yeej zoo tshaj plaws rau hom machining. Yog tias siv cov cemented carbide insert, nws yuav ntsib teeb meem ntawm kev hnav ntau dhau thaum cov hniav txiav ib qho nyuaj, yog tias CBN ntxig haum rau kev txiav cov ntaub ntawv nyuaj yog siv los txiav cov mos mos, nws yooj yim rau kev puas tsuaj. Peb tuaj yeem siv qhov kev sib haum xeeb: siab hardness carbide inserts + super lubricated coatings, los yog kuj muag CBN ntxig qib + txiav inserts haum rau kev txiav cov khoom siv (ntau dua li hard machining).

Drape tau hais tias, "Koj tuaj yeem siv CBN inserts los txiav cov khoom ua haujlwm zoo nrog lub hardness ntawm 45-50 HRC, tab sis cov hniav geometry yuav tsum tau kho. Hom CBN inserts muaj qhov tsis zoo chamfer ntawm qhov txiav ntug. Qhov tsis zoo chamfer CBN ntxig yog softer rau tshuab. Thaum siv cov khoom siv ua haujlwm, cov khoom siv yuav muaj qhov rub tawm thiab lub cuab yeej lub neej yuav luv. Yog tias qib CBN nrog qis hardness yog siv thiab cov geometry ntawm kev txiav ntug yog hloov, cov khoom siv workpiece nrog hardness ntawm 45-50 HRC tuaj yeem ua tiav txiav. "

S117 HORN grooving insert tsim los ntawm lub tuam txhab siv lub hau PCBN, thiab qhov tob ntawm kev txiav yog hais txog 0.15-0.2 hli thaum lub iav dav yog qhov tseeb txiav. Txhawm rau ua kom tiav qhov zoo ntawm qhov tiav, cov hniav muaj lub dav hlau scraping ntawm txhua qhov txiav ntawm ob sab.

Lwm qhov kev xaiv yog hloov cov kev txiav txiav. Raws li Index's Economan, "Tom qab txiav los ntawm cov txheej tawv tawv, kev txiav loj tuaj yeem siv tau. Yog hais tias qhov tob hardened tsuas yog 0.13mm lossis 0.25mm, tom qab txiav los ntawm qhov tob no, cov hniav sib txawv yog hloov los yog tseem siv tib cov hniav, tab sis nce qhov txiav txiav mus rau theem tsim nyog. "

Txhawm rau txhawm rau txhawm rau txhawm rau ua tiav ntau yam, cov qib PCBN hniav tau nce ntxiv. Cov qib hardness siab dua tso cai rau kev txiav nrawm dua, thaum cov qhab nia zoo dua tuaj yeem siv rau hauv qhov chaw ua haujlwm tsis ruaj khov. Rau kev txiav tsis tu ncua lossis cuam tshuam, sib txawv PCBN ntxig qib tuaj yeem siv tau. Sumitomo Electric's Maton tau taw qhia tias vim qhov brittleness ntawm PCBN cov cuab yeej, cov npoo ntse ntse yog qhov ua rau chipping thaum machining hardened steel. "Peb yuav tsum tiv thaiv cov ntug txiav, tshwj xeeb tshaj yog nyob rau hauv kev cuam tshuam kev txiav, txiav ntug yuav tsum tau npaj ntau tshaj li nyob rau hauv tas li ntawd txiav, thiab txiav lub kaum sab xis yuav tsum loj dua."

Iskar tau tsim tshiab IB10H thiab IB20H qib ntxiv nthuav dav nws Groove Turn PCBN cov khoom lag luam. IB10H yog qib zoo-grained PCBN rau nruab nrab mus rau kev kub ceev nruam txiav ntawm hardened steel; thaum IB20H muaj cov nplua thiab nruab nrab cov nplej loj PCBN nplej, muab kev hnav zoo thiab cuam tshuam. Qhov sib npaug tuaj yeem tiv taus cov xwm txheej hnyav ntawm cov hlau tawv tawv cuam tshuam kev txiav. Hom tsis ua haujlwm ib txwm muaj ntawm PCBN cov cuab yeej yuav tsum yog qhov txiav ntug hnaves tsis txhob tam sim ntawd tawg los yog tawg.

BNC30G coated PCBN qib qhia los ntawm Sumitomo Electric yog siv rau kev cuam tshuam grooving ntawm hardened steel workpieces. Rau kev nruam grooving, lub tuam txhab pom zoo nws BN250 universal hniav qib. Maton tau hais tias, “Thaum txiav tsis tu ncua, cov hniav raug txiav rau lub sijhawm ntev, uas yuav ua kom muaj cua sov ntau heev. Yog li ntawd, nws yog ib qho tsim nyog yuav tau siv cov hniav nrog zoo hnav tsis kam. Nyob rau hauv cov ntaub ntawv ntawm intermittent grooving, cov hniav tsis tu ncua nkag thiab tawm txiav. Nws muaj kev cuam tshuam zoo rau lub ntsis. Yog li ntawd, nws yog ib qho tsim nyog yuav tau siv cov hniav nrog zoo toughness thiab tuaj yeem tiv taus qhov cuam tshuam tsis sib xws. Tsis tas li ntawd, cov hniav txheej kuj yuav pab kom ntev lub cuab yeej. "

Txawm hais tias hom groove yog machined, cov kev cob qhia uas yav tas los tso siab rau kev sib tsoo kom tiav cov hlau tawv tawv tuaj yeem hloov mus rau grooving nrog PCBN cov cuab yeej los ua kom cov khoom tsim tau. Hard grooving tuaj yeem ua tiav qhov tseeb qhov tseeb piv rau kev sib tsoo, thaum txo qis lub sijhawm ua haujlwm.