Ukusetyenziswa okuchanekileyo kwe-End Mill

Ukusetyenziswa ngokuchanekileyo komatshini wokusila

Xa ukungqusha workpieces entsonkothileyo kwiziko machining machining, ezi ngxaki zilandelayo kufuneka ingqalelo xa usebenzisa ulawulo lwamanani ekupheleni milling cutter:

1. I-end milling cutter esetyenziswa kwiziko lokucoca i-clamping ye-end milling cutter ikakhulu ithatha imowudi yokudibanisa i-spring clamp, ekwimeko ye-cantilever xa isetyenziswa. Kwinkqubo yokusila, ngamanye amaxesha isiphelo sokusila sinokuthi ngokuthe ngcembe siphume kwisibambi sesixhobo, okanye side siwise ngokupheleleyo, okukhokelela kwinto yokulahlwa kwesixhobo sokusebenza. Ngokubanzi, isizathu sesokuba kukho ifilimu yeoli phakathi komngxuma ongaphakathi wesibambi isixhobo kunye nedayamitha engaphandle ye-milling cutter shank, ekhokelela ekungoneleni kwamandla okubamba. I-end milling cutter idla ngokuqatywa nge-oyile ye-antirust xa ishiya umzi-mveliso. Ukuba ioli yokusika engenamanzi isetyenziswe ngexesha lokusika, umngxuma wangaphakathi we-cutter holder uya kuhlonyelwa kunye noluhlu lwenkungu njengefilimu yeoli. Xa kukho ifilimu yeoli kwi-handle kunye nomphathi we-cutter, kunzima kumnini we-cutter ukuba abambe ngokuqinileyo isibambo, kwaye i-milling cutter iya kuba lula ukukhulula kunye nokuwa ngexesha lokucubungula. Ngoko ke, ngaphambi kokuba isiphelo sokusika i-milling cutter sinyanzeliswe, umqheba we-end milling cutter kunye nomngxuma wangaphakathi we-cutter clamp uya kucocwa ngokucoca ulwelo kwaye emva koko ugxininiswe emva kokuba usomisiwe. Xa i-diameter ye-end mill inkulu, nokuba i-handle kunye ne-clamp zicocekile, umsiki unokuwa. Kule meko, i-handle ene-notch flat kunye nendlela yokuvala icala elihambelanayo kufuneka ikhethwe.

2. Ukungcangcazela kwelitye lokuphela

Ngenxa yesikhewu esincinci phakathi komsiki wokusila kunye ne-cutter clamp, umsiki unokungcangcazela ngexesha lenkqubo yomatshini. I-vibration iya kwenza isixa sokusika somda wesetyhula we-milling cutter yokuphela ingalingani, kwaye ukwandiswa kokusika kukhulu kunexabiso elimiselweyo lokuqala, eliya kuchaphazela ukuchaneka komatshini kunye nobomi benkonzo ye-cutter. Nangona kunjalo, xa ububanzi be-groove buncinci kakhulu, isixhobo sinokungcangcazela ngenjongo, kwaye ububanzi be-groove obufunekayo bunokufumaneka ngokunyusa ukwandiswa kokusika, kodwa kulo mzekelo, ubuninzi be-amplitude yokugqibela kufuneka bube ngaphantsi kwe-0.02mm, ngaphandle koko ukusika okuzinzileyo akunakwenziwa. Okuncinci ukungcangcazela kwe-milling cutter engathathi hlangothi, kungcono. Xa ukunyakaza kwesixhobo kwenzeka, isantya sokusika kunye nesantya sokutya kufuneka sincitshiswe. Ukuba kusekho i-vibration enkulu emva kokuba zombini zincitshiswe ngama-40%, umthamo wesixhobo se-snack kufuneka uncitshiswe. Ukuba i-resonance iyenzeka kwisixokelelwano somatshini, inokubangelwa zizinto ezifana nesantya sokusika ngokugqithisileyo, ukungonelanga kobulukhuni benkqubo yesixhobo ngenxa yokutenxa kwesantya sokutya, ukungonelanga kwamandla obambelelo kwisixhobo sokusebenza, kunye nokumila kwesixhobo sokusebenza okanye indlela yokubamba. Ngeli xesha, kuyimfuneko ukulungelelanisa inani lokusika kunye nokwandisa inani lokusika.

Ukuqina kwenkqubo yesixhobo kunye nokuphuculwa kwesantya sokutya.

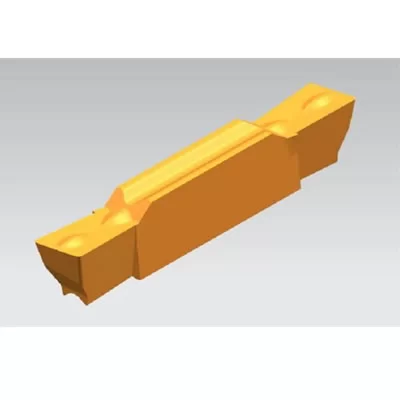

3. Ukuphelisa ukusika isiphelo sokusika umsiki

Kwi-NC yokusila yomgodi wokufa, xa inqaku eliza kunqunyulwa liyinxalenye ye-concave okanye i-cavity enzulu, kuyimfuneko ukwandisa ukongezwa komsiki wokuphela kokugaya. Ukuba isiphelo somphetho omde siyasetyenziswa, kulula ukuvelisa ukungcangcazela kwaye kubangele umonakalo wesixhobo ngenxa yokuphambuka kwawo okukhulu. Ngoko ke, kwinkqubo yokucoca, ukuba kuphela umgca wokusika kufuphi nesiphelo sesixhobo esifunekayo ukuba uthathe inxaxheba ekusikeni, kungcono ukhethe umphetho omfutshane we-shank end mill kunye nobude obude besixhobo. Xa isiphelo sokusila ubukhulu obukhulu sisetyenziswa kwisixhobo somatshini esithe tye CNC ukusetyenzwa kwezixhobo zokusebenza, ngenxa yoguquko olukhulu olubangelwa ubunzima obufileyo besixhobo, kufuneka kuqwalaselwe ngakumbi iingxaki ezilula ukuba zenzeke ekugqibeleni ukusika. Xa kufuneka kusetyenziswe i-long edge end Mill, isantya sokusika kunye nesantya sokutya kufuneka sincitshiswe kakhulu.

4. Ukukhethwa kweparamet yokusikaers

Ukukhethwa kwesantya sokusika ikakhulu kuxhomekeke kwizinto eziphathekayo zokwenziwa komsebenzi; ukhetho lwesantya sokutya ikakhulu kuxhomekeke kwizinto zokusebenza eziza kucutshungulwa kunye nobubanzi bomngqusho wokuphela. Iisampulu zesixhobo ezivela kwabanye abavelisi bezixhobo zangaphandle zincanyathiselwe kunye netafile yokukhetha ipharamitha yesixhobo sokujonga. Nangona kunjalo, ukhetho lweeparamitha zokusika luchatshazelwa zizinto ezininzi ezifana nesixhobo somatshini, inkqubo yesixhobo, imilo yomsebenzi oza kucutshungulwa kunye nendlela yokudibanisa. Isantya sokusika kunye nesantya sokutya kufuneka sihlengahlengiswe ngokweyona meko. Xa ubomi besixhobo buyinto ephambili, isantya sokusika kunye nesantya sokutya sinokuncitshiswa ngokufanelekileyo; xa i-chip ingekho kwimeko efanelekileyo, isantya sokusika sinokunyuswa ngokufanelekileyo.

5. Ukukhethwa kwendlela yokusika

Ukusetyenziswa kwe-down milling kunenzuzo ukukhusela umonakalo we-blade kunye nokuphucula ubomi besixhobo. Nangona kunjalo, amanqaku amabini kufuneka aqatshelwe: ① ukuba izixhobo zoomatshini eziqhelekileyo zisetyenziselwa umatshini, kuyimfuneko ukususa umsantsa phakathi kwendlela yokutyisa; ② xa kukho ifilimu ye-oxide okanye enye umaleko oqinayo owenziwe ngokuphosa kunye nenkqubo yokubumba kumphezulu we-workpiece, kuyacetyiswa ukuba kusetyenziswe i-reverse milling.

6. Ukusetyenziswa kwee-carbide end Mills

Iintsimbi zokuphela kwesantya esiphezulu zineendlela ezininzi zokusetyenziswa kunye neemfuno. Nangona iimeko zokusika azikhethwanga ngokufanelekileyo, akuyi kuba neengxaki ezininzi. Nangona i-carbide end milling cutter inokumelana nokunxiba kakuhle kwi-high-speed cutting, uluhlu lwesicelo sayo alunabubanzi njengoko i-high-speed steel end milling cutter, kwaye iimeko zokusika kufuneka zihlangabezane ngokungqongqo neemfuno zokusetyenziswa komsiki.