Sarudzo yeLathe Indexable Blade (CNC Blade)

Mushure mekuwana iyo workpiece dhizaini, tanga wasarudza indexable blade ine chimiro chakakodzera zvinoenderana nezvinodiwa zvekudhirowa. Kazhinji, lathe inonyanya kushandiswa kushandura denderedzwa rekunze negomba remukati, kucheka nekucheka groove, uye kushandura shinda. Kusarudzwa kweblade kunotarirwa maererano nemamiriro chaiwo ekugadzirisa teknolojia. Kazhinji, mablades ane high versatility uye mamwe macheto ekucheka pane imwechete blade inofanira kusarudzwa. Sarudza saizi hombe yekutenderedza uye diki saizi yekutenderera uye semi fine kutendeuka. Zvinoenderana nezvinodiwa zvetekinoroji, isu tinosarudza iyo inodiwa blade chimiro, yekucheka kumucheto kureba, tip arc, blade ukobvu, blade back angle uye blade kunyatsoita.

一. Sarudza chimiro cheblade

1. Iyo blade yekunze denderedzwaS-maumbirwo: mana ekucheka macheto, ane mapfupi ekucheka (tarisa kune imwechete yemukati yekucheka denderedzwa dhayamita), simba rakakwirira rekushandisa tip, rinonyanya kushandiswa 75 ° uye 45 ° kushandura maturusi, uye anoshandiswa kugadzirisa kuburikidza-gomba mune zvemukati gomba maturusi.

T-chimiro: mativi matatu ekucheka, kureba kwekucheka uye kuderera kwesimba remuromo. Iyo blade ine yekubatsira deflection angle inowanzo shandiswa pane general lathe kuvandudza kusimba kwetip. Inonyanya kushandiswa 90 ° kutendeuka maturusi. Iyo yemukati gomba inotenderedza chishandiso inonyanya kushandiswa kugadzira mapofu maburi uye nhanho maburi.

C chimiro: kune marudzi maviri emakona akapinza. Simba remazano maviri e100 ° anopinza kona akakwira, kazhinji anogadzirwa kuita 75 ° inotenderedza chishandiso, iyo inoshandiswa kuita rough kushandura denderedzwa rekunze uye yekupedzisira kumeso. Simba remapendero maviri e80 ° inopinza angle yakakwira, iyo inogona kushandiswa kugadzirisa iyo yekupedzisira kumeso kana cylindrical pamusoro pasina kushandura chishandiso. Iyo yemukati gomba inotenderedza chishandiso chinowanzo shandiswa kugadzirisa gomba renhanho.

R-chimiro: kumucheto, kunoshandiswa kugadzira yakakosha arc pamusoro, yakakwirira yekushandiswa mwero weblade, asi yakakura radial simba.

W chimiro: matatu ekucheka micheto uye mapfupi, 80 ° inopinza kona, simba rakakwirira, rinonyanya kushandiswa kugadzira cylindrical pamusoro uye nhanho yepasi pane general lathe.

D-chimiro: mapeji maviri ekucheka akareba, kona yekucheka ndeye 55 ° uye simba rekucheka rakaderera, iro rinonyanya kushandiswa pakugadzira profiling. Paunenge uchigadzira 93 ° kutendeuka chishandiso, kona yekucheka haizove yakakura kupfuura 27 ° - 30 °; paunenge uchigadzira 62.5 ° inoshandura chigadziro, kona yekucheka haifaniri kunge yakakura kudarika 57 ° - 60 °, iyo inogona kushandiswa kune nhanho gomba uye kudzika midzi yekuchenesa paunenge uchigadzira mukati megomba.

V chimiro: mativi maviri ekucheka uye kureba, 35 ° inopinza kona, simba rakaderera, rinoshandiswa kuporofita. Paunenge uchigadzira 93 ° kutendeuka chishandiso, kona yekucheka haizove yakakura kupfuura 50 °; pakuita 72.5 ° kutendeuka chishandiso, kona yekucheka haizove yakakura kupfuura 70 °; pakuita 107.5 ° kutendeuka chishandiso, kona yekucheka haizove yakakura kupfuura 35 °.

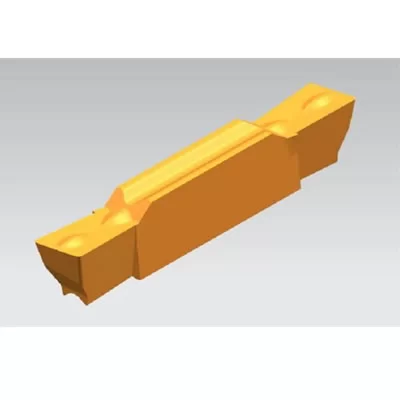

2. Kucheka nekugera mapanga:

1) blade yekucheka:

MuCNC lathe, blade yekucheka inowanzo shandiswa kudzvanya chip breaking groove chimiro zvakananga. Inogona kuita kuti machipisi aderedze uye agokanganisa padivi, akacheka nyore uye akavimbika. Uye zvakare, ine yakakura side deflection angle uye kumashure angle, kushoma kucheka kupisa, hupenyu hurefu hwebasa uye mutengo wepamusoro.

2) grooving blade: kazhinji, blade yekucheka inoshandiswa kucheka gomba rakadzika, uye blade yekugadzira inoshandiswa kucheka gomba risina kudzika, sezvinotevera: vertical grooving blade, flat grooving blade, strip grooving blade, arc yekuchenesa nhanho. mudzi groove blade. Aya mablades ane yakakwirira groove hupamhi hwechokwadi.

3. Thread blade: L-shaped blade inowanzoshandiswa, inogona kuva reground uye yakachipa, asi haigoni kucheka pamusoro pezino. Iyo shinda ine yakakwirira yekucheka kurongeka inoda kushandisa blade ine yakanaka profile kugaya. Nekuti shinda yemukati neyekunze ine hukuru hwakasiyana hukuru, dzakakamurwa kuita mukati nekunze tambo blades. Chimiro chavo chakagadziriswa uye chinogona kutemwa kunze kwekorona. Se clampingnzira, inogona kupatsanurwa mumhando mbiri: imwe ipanga isina gomba, iyo inosungirirwa nekudzvanya kumusoro. Paunenge uchigadzira zvinhu zvine purasitiki yakakwira, blade iyi inodawo kuwedzera baffle plate; imwe yacho iblade ine buri rinosunga uye chip breaking groove, iyo inosungwa nepuraramu sikuru ine buri rekumanikidza.

二. Kucheka kumucheto kureba

Kucheka kumucheto kureba: ichasarudzwa maererano nekunyorwa kwemashure. Kazhinji, kureba kwekucheka kwekucheka kwemukati we groove blade kuchava ≥ 1.5 nguva dzechinyorwa chemashure, uye kureba kwekucheka kwekucheka kwekavha yakavharwa blade kuchava ≥ 2 nguva dzekudzokera shure.

三. muromo arc

Tip arc: chero kuomarara kuchitenderwa kutenderedza, iyo hombe tip arc radius inogona kushandiswa kure sezvinobvira, nepo diki arc radius ichiwanzo shandiswa kutenderera zvakanaka. Zvisinei, kana kuomarara kuchibvumirwa, kunofanirawo kusarudzwa kubva pakukosha kukuru, uye iyo inowanzoshandiswa yakatsikirirwa inoumba denderedzwa radius ndeye 0.4; 0.8; 1.2; 2.4, nezvimwewo.

四. blade ukobvu

Ukuru hweblade: sarudzo yekusarudza ndeyekuita kuti blade ive nesimba rakakwana kutakura simba rekucheka, iro rinowanzosarudzwa maererano nemusana wekudya uye chikafu. Semuenzaniso, mamwe mashizha e ceramic anofanirwa kusarudza mashizha akakora.

五. kumashure kwekona yeblade

Blade back angle: inowanzoshandiswa:

0 ° kodhi n;

5 ° kodhi B;

7 ° kodhi C;

11 ° kodhi P.

0 ° kumashure kona inowanzo shandiswa kuita rough uye semi finish kutendeuka, 5 °; 7 °; 11 °, inowanzo shandiswa semi kupedzisa, kupedzisa kutendeuka, kunyora uye kugadzira maburi emukati.

六. blade kururama

Kurongeka kweblade: kune marudzi gumi nematanhatu ehutsanana hwakatsanangurwa nenyika kune mablade ane indexable, pakati pawo marudzi matanhatu akakodzera kushandura maturusi, kodhi h, e, G, m, N, u, h ndiyo yepamusoro-soro, u ndiye yakaderera, u inoshandiswa kuita rough uye semi finish machining ye general lathe, M inoshandiswa CNC lathe kana m inoshandiswa CNC lathe, uye G inoshandiswa padanho repamusoro.

Mushure mematanho ari pamusoro, isu takaona kuti rudzii rweblade runofanira kushandiswa. Muchinhanho chinotevera, tinoda kuenderera mberi nekutarisa masampuli emagetsi evagadziri veblade, uye pakupedzisira kuona rudzi rweblade inoshandiswa maererano nemidziyo uye nemazvo kuti agadziriswe.