Kushandiswa Kwazvo KweEnd Mill

Kushandiswa chaiko kweend mill

Paunenge uchikuya zvimedu zvekugadzira pamilling machining Center, iwo anotevera matambudziko anofanirwa kutariswa kana uchishandisa nhamba yekudzora kupera milling cutter:

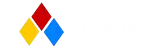

1. Iyo yekupedzisira milling cutter inoshandiswa mu clamping machining center ye end milling cutter kazhinji inotora chitubu clamp set clamp mode, iri mu cantilever state kana ichishandiswa. Mukuita kugaya, dzimwe nguva magumo ekucheka anogona kuwedzera zvishoma nezvishoma kunze kwechibatiso, kana kutodonha zvachose, zvichikonzera chiitiko chekuraswa kweworkpiece. Kazhinji, chikonzero ndechekuti pane firimu remafuta pakati pegomba remukati memudziyo wemidziyo uye dhayamita rekunze rekupedzisira milling cutter shank, zvichikonzera kusakwana kwesimba rekusunga. Iyo yekupedzisira milling cutter inowanzoputirwa nemafuta e-antirust kana ichibva mufekitori. Kana iyo isiri-mvura yakanyungudutswa yekucheka mafuta inoshandiswa panguva yekucheka, gomba remukati remubati wekucheka richabatanidzwawo nehupamhi hwemhute semafuta firimu. Kana paine firimu remafuta pamubato uye chibatiso chekucheka, zvakaoma kuti mucheki asimbise mubato, uye mucheki weguyo unova nyore kusunungura uye kudonha panguva yekugadzirisa. Naizvozvo, iyo yekupedzisira milling cutter isati yasungwa, mubato wekupedzisira milling cutter uye gomba remukati reiyo cutter clamp ichacheneswa nekuchenesa mvura uye yobva yasungwa mushure mekuomeswa. Kana iyo dhayamita yeguyo yekupedzisira yakakura, kunyangwe mubato uye mbambo zvakachena, mucheki anogona kudonha. Muchiitiko ichi, mubato une flat notch uye inopindirana nzira yekuvhara nzira inofanira kusarudzwa.

2. Kudengenyeka kweguyo rekupedzisira

Nekuda kwemukana mudiki pakati pekupedzisira milling cutter uye cutter clamp, mucheki anogona kudedera panguva yekugadzira machining. Kudengenyeka kuchaita kuti chidimbu chekucheka chechidimbu chechidimbu chekupedzisira chekucheka chigayo chisina kuenzana, uye kuwedzera kwekucheka kwakakura kudarika kukosha kwepakutanga, izvo zvichakanganisa machining kururama uye hupenyu hwebasa remucheki. Nekudaro, kana iyo groove yakafara idiki kwazvo, chishandiso chinogona kudedera zvine chinangwa, uye inodiwa groove hupamhi inogona kuwanikwa nekuwedzera kuchekwa kwekuwedzera, asi mune iyi kesi, iyo yakanyanya amplitude yeguyo yekupedzisira inofanira kuganhurwa pazasi 0.02mm, zvikasadaro. kucheka kwakadzikama hakugone kuitwa. Iyo idiki iyo vibrate yeyairerekera milling cutter iri, zviri nani. Kana iyo vibration yekushandisa ikaitika, kumhanya kwekucheka uye kumhanya kwekudya kunofanirwa kudzikiswa. Kana kuchine kuzunguzika kukuru mushure mekunge zvese zvadzikiswa ne40%, huwandu hwechikafu chekushandisa hunofanira kuderedzwa. Kana resonance ikaitika mumachining system, inogona kukonzerwa nezvinhu zvakaita senge yakawandisa yekucheka kumhanya, kusakwana kuomarara kwechishandiso system nekuda kwekumhanya kwekudya kutsauka, kusakwana kwesimba rekumanikidza reworkpiece, uye workpiece chimiro kana clamping nzira. Panguva ino, zvakakosha kugadzirisa chiyero chekucheka uye kuwedzera chiyero chekucheka.

Iko kuomarara kwechishandiso sisitimu uye kuvandudzwa kwekumhanyisa kwekudya.

3. Kupedza kucheka kwekupedzisira milling cutter

Mune NC milling yefa mhango, kana iyo poindi ichatemwa iri concave chikamu kana yakadzika mhango, zvinodikanwa kuti uwedzere kuwedzera kwekupedzisira milling cutter. Kana chigayo chakareba chekupedzisira chikashandiswa, zviri nyore kugadzira vibration uye kukonzera kukuvara kwechishandiso nekuda kwekutsauka kwayo kukuru. Naizvozvo, mukuita machining, kana chete kucheka kumucheto pedyo nekuguma kwechishandiso kunodiwa kuti utore chikamu mukucheka, zviri nani kusarudza pfupi kumucheto refu shank end mill nehurefu hurefu hwechishandiso. Kana yakakura dhayamita yekupedzisira chigayo ichishandiswa mune yakachinjika CNC muchina chishandiso chekugadzirisa workpieces, nekuda kweiyo deformation yakakura inokonzerwa nehuremu hwakafa hwechishandiso, kutarisisa kwakanyanya kunofanirwa kubhadharwa kune matambudziko ari nyore kuitika mukupedzisira kucheka. Kana chigayo chakareba chekupedzisira chikashandiswa, kumhanya kwekucheka uye kumhanya kwekudya kunoda kuderedzwa zvakanyanya.

4. Kusarudzwa kwekucheka parameters

Kusarudzwa kwekucheka kukurumidza kunonyanya kuenderana nezvinhu zve workpiece kuti zvigadziriswe; kusarudzwa kwekumhanyisa kwekudya kunonyanya kuenderana nezvinhu zvebasa rinofanirwa kugadziriswa uye dhayamita yeguyo rekupedzisira. Zvishandiso sampuli kubva kune vamwe vagadziri vezvishandiso zvekune dzimwe nyika zvakanamirwa neturusi yekucheka paramende tafura yekutarisa. Nekudaro, kusarudzwa kwemaparamendi ekucheka kunokanganiswa nezvakawanda zvinhu zvakaita semuchina chishandiso, chishandiso system, chimiro cheworkpiece kuti igadziriswe uye clamping nzira. Iyo yekucheka kumhanya uye kukurumidza kwekudya kunofanirwa kugadziridzwa zvinoenderana nemamiriro chaiwo. Kana hupenyu hwekushandisa huri hwekutanga, kukurumidza kucheka uye kukurumidza kwekudya kunogona kuderedzwa nemazvo; apo chip chinenge chisina kumira zvakanaka, kasi yekucheka inogona kuwedzerwa zvakanaka.

5. Kusarudzwa kwekucheka mode

Kushandiswa kwechigayo kunobatsira kudzivirira kukuvara kweblade uye kugadzirisa hupenyu hwemidziyo. Nekudaro, mapoinzi maviri anofanirwa kucherechedzwa: ① kana maturusi emuchina akajairwa achishandiswa kugadzira, zvakakosha kubvisa mukaha uripo pakati pemakina ekudyisa; ② kana paine oxide firimu kana imwe yakaomeswa layer yakaumbwa nekukandira nekugadzira nzira pamusoro peiyo workpiece, zvinokurudzirwa kushandisa reverse milling.

6. Kushandisa carbide end mills

High-speed steel end mills vane hupamhi hwekushandisa uye zvinodiwa. Kunyange kana mamiriro ekucheka asina kusarudzwa zvakanaka, hapazovi nematambudziko akawanda. Kunyange zvazvo carbide end milling cutter ine yakanaka kupfeka kusagadzikana mu-high-speed cutter, kushandiswa kwayo hakuna kufanana neyepamusoro-speed steel end milling cutter, uye mamiriro ekucheka anofanira kunyatsosangana nezvinodiwa zvekushandisa zvekucheka.